7 Exactly How To Make A Concrete Formwork - Consequently, you have to read the foundation plans, to see the height of the foundation elevation from the ground. When you’re ready to ditch timber, we’ll be waiting for you with our concrete boxing system.

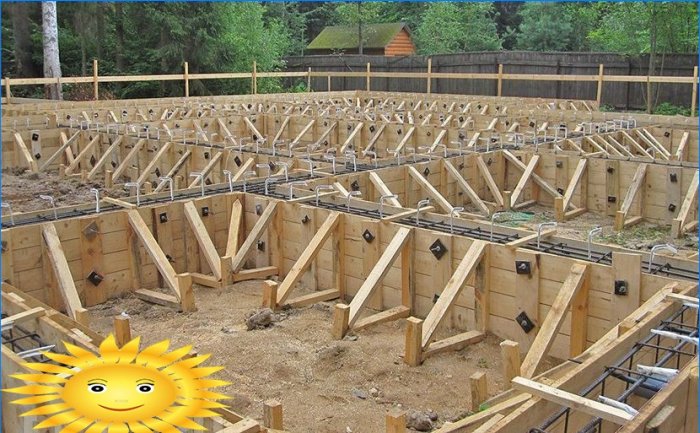

Design Needs For Concrete Formwork In Sydney . Next you have to build the formwork panels, as you can see in the image.

Design Needs For Concrete Formwork In Sydney . Next you have to build the formwork panels, as you can see in the image.

How to make a concrete formwork

9 Useful How To Make A Concrete Formwork. Salt in concrete will slightly increase the strength, but if for any reason you have to use reinforcement or embedment then there is a problem; Generally, the base plate is the exact size and shape of the finished concrete piece. Formwork (shuttering) is temporary support as a mould for fresh concrete, in which concrete is poured and cast in the desired shape and gain initial strength, hardened and matured. How to make a concrete formwork

Set and level one side cut a 2x12 to length (or splice it with a cleat) for one side of the It should be done for at least 6 inches. Our concrete formwork system was designed to make your job easier and less messy than when you use timber or plywood. How to make a concrete formwork

Does adding salt to concrete make it 1.4 x stronger? We’ve been using msb form since 2014, and without it, we wouldn’t be as efficient as we are today. Use a shovel to level out the area you are planning to concrete. How to make a concrete formwork

Peg the horizontal braces at their rear ends, again at least six inches deep. Empty the concrete mix blend slowly into the water and mix thoroughly. 1 make a straight edge with formwork. How to make a concrete formwork

When fastening the 2×4 pegs. Formwork is used in different shapes and sizes according to our construction elements in the form of pcc, rcc works in building , bridge, tunnel lining, hydropower dam, irrigation. Step 7 lay polythene sheeting and tape. How to make a concrete formwork

They also help ensure the formwork stays clean and free from. The amount of pressure at any point on the form is directly determined by the height and weight of concrete above it. Before concrete hardens, it acts like a liquid and pushes against the forms the way water presses against the walls of a storage tank. How to make a concrete formwork

We show you the best techniques for concrete forms. All formwork, whether is be steel roadform or timber shuttering, needs to be coated with a release agent (mould oil) before any concrete is placed. It is made of either How to make a concrete formwork

Formwork used to hold concrete in a certain shape while the mixture hardens and therefore is an important part of many concrete jobs. Add water (1.75 litres of clean water per bag of concrete mix) to the mixing vessel. If you build the concrete stairs in the garden or park, remove the topsoil or grass by digging down. How to make a concrete formwork

The size of the completed box is determined by the desired thickness of the slab, the thickness of the forming material and how the sides are fastened to the box. For example, most melamine is ¾ inch (or 0.75 inch) thick, or 19 mm thick. Slab on grade there are polystyrene and plastic dome systems available for residential or light commercial slab on grade and are sometimes referred to as permanent formwork, although. How to make a concrete formwork

Then put a piece of formwork in the position you want for the edge of. Next, fill the area with crushed rock or gravel. The purpose of a release agent is to prevent the concrete bonding to the formwork and then 'scabbing' when the formwork is removed. How to make a concrete formwork

Make sure that the ground on the front of the door is level. It should be 6 inches wider than the size of the concrete stairs. Step 6 erect formwork for the slab along the outer edges of the building footprint the formwork will provide the shape of the slab and hold the concrete while it dries. How to make a concrete formwork

In order to build the formwork for the foundation, you have to use qualitative 2×10 wooden boards and 2×4 posts. 1) height of concrete pour: The formwork build for the laying of concrete is fixed with the chamfer strip at the edge. How to make a concrete formwork

Your rebar will start rusting straight away, consequently your concrete will start cracking as the bars start rusting. Depending on the requirement of chamfered edge size, chamfer strips are available in the sizes of 1/2, 3/4 and 1 inches. This creates strong triangular supports at the back of the formwork. How to make a concrete formwork

Timber used for shuttering for exposed concrete work should have smooth and even surface on all faces which come in contact with concrete. Insulating concrete formwork (icf) is a type of vertical permanent formwork made of expanded polystyrene blocks into which reinforcing steel and concrete are placed. How to make a concrete formwork

How to build concrete stairs HowToSpecialist How to . Insulating concrete formwork (icf) is a type of vertical permanent formwork made of expanded polystyrene blocks into which reinforcing steel and concrete are placed.

Build Concrete Steps Step by Step Guide . Timber used for shuttering for exposed concrete work should have smooth and even surface on all faces which come in contact with concrete.

Build Concrete Steps Step by Step Guide . Timber used for shuttering for exposed concrete work should have smooth and even surface on all faces which come in contact with concrete.

How to build formwork HowToSpecialist How to Build . This creates strong triangular supports at the back of the formwork.

How to make foundation formwork . Depending on the requirement of chamfered edge size, chamfer strips are available in the sizes of 1/2, 3/4 and 1 inches.

How to make foundation formwork . Depending on the requirement of chamfered edge size, chamfer strips are available in the sizes of 1/2, 3/4 and 1 inches.

PSL Architects The Serrano Concrete deck formwork . Your rebar will start rusting straight away, consequently your concrete will start cracking as the bars start rusting.

PSL Architects The Serrano Concrete deck formwork . Your rebar will start rusting straight away, consequently your concrete will start cracking as the bars start rusting.

How to Build a Concrete Porch/Stoop (Framing, Mixing . The formwork build for the laying of concrete is fixed with the chamfer strip at the edge.